Mixed Gas and Rebreathers

SAFETY WARNING

NEVER, EVER DIVE A HELMET OR ANY EQUIPMENT UNLESS YOU ARE ABSOLUTELY SURE IT IS GENUINE AND IN PROPER WORKING CONDITION. Replica helmets are not designed or built for actual use. Attempting to dive a replica helmet could result in serious injury or death. Only dive after you have received the proper training.

Mixed Gas and DESCO

In 1935 Max Nohl had his sights set on salvaging the cargo of the Prohibition rum runner John Dwight. At this time Max made his connection to John D. Craig. John Craig owned the film rights to the sunken Liner RMS Lusitania. Nohl had already been working on diving equipment to work at the Lusitania’s depth. Additional support equipment would need to be designed and built for the project. Nohl using the suit design from his MIT thesis as a starting point began experimentation on building the necessary gear.

Another Milwaukee native, Jack Browne came onboard. Jack had worked with Nohl on salvaging the steamer Westmoreland in 1936. The third man in the story was Dr. Edgar End. Dr. End was a graduate of the Marquette University Medical School and was a practicing physician. He served as Assistant Clinical Professor of Environmental Medicine at Marquette. In this capacity he was studying the effects of Caisson Disease on Milwaukee tunnel workers. In April 1937 Max Nohl contacted Dr. End about his development of Helium/ Oxygen decompression tables. Dr. End suggested using the recompression chamber in the basement of the Milwaukee County Hospital to test their theories. Their collaboration moved the development of the new equipment and the necessary background knowledge forward.

Browne and Nohl worked together on the design of a new type of lightweight, self-contained diving suit. At the same time they worked with Dr. End to explore the promising possibility of preventing nitrogen narcosis by having the diver breathe a mixture of helium and oxygen rather than air.

On December 1, 1937 in Lake Michigan, Max Nohl succeeded in diving to a depth of 420 feet, thereby breaking a depth record which had been held by a U.S. Navy diver Frank Crilley, since 1915. Nohl accomplished this feat using DESCO's new diving equipment and breathing a heliox mixture prescribed by Dr. End. Ironically as war neared in Europe the British Admiralty began placing more and more restrictions on John Craig’s expedition so it was finally called off. The experiences of designing, constructing, and testing the equipment for the Lusitania expedition would pay large dividends in the near future.

Concurrently the U.S. Navy, under Dr. Albert Behnke and Cmdr Swede Momsen, was developing the equipment and techniques the that would be needed by military divers. The opportunity to test the techniques and equipment came when USS Squalus sank in 1939. The successful recovery of the Squalus proved the feasibility of deep mixed gas diving to the military and civilian ranks.

The outbreak of war shifted DESCO's focus from experimental diving to standard diving equipment production. World War II brought large Navy contracts for diving equipment to DESCO. The company’s research and development roots were not overlooked by the government. DESCO was contracted by the Office of Strategic Services (forerunner of the CIA) to design and build a compact oxygen rebreather. The result was the DESCO B-Lung. This unit, for the first time, permitted divers to swim freely under the surface, in the manner of SCUBA divers today, but without producing bubbles, which might disclose their position. Other projects included the Browne Utility Mixed Gas Helmet which morphed into the Buie Mixed Gas Helmet.

DESCO Helium Recirculating Helmets

U. S. Navy Helium Helmet

The U.S. Navy Helium Helmet is a offshoot of the USN Mark V Diving Helmet. The air inlet and communication elbows are moved up to allow for a canister attachment to the back of the bonnet. The Spitcock is deleted and the helmet lock is relocated to that position.

On war years Helium helmets the exhaust tube running over the top of the bonnet terminated in a perforated bulb like the banana exhaust on the Mark V.

In the early 1950's a secondary double exhaust was installed to prevent leak back of water into the helmet. The scrubbing medium being used during the war was shell natron. It reacted with salt water and produced Chlorine gas. A accident of this kind would lead to severe injury and often death to the diver. Later on the shell natron was replaced with Baralyme which was safer. Water intrusion could still create problems with the Baralyme as it would reduce the effectiveness.

Model 100 Helmet

We know very little about the Model 100 or the Model 106. Recently while researching something else online we came across the Jack Browne patent for the Model 100. The patent application was filed in January of 1942 which logic leads us to believe the design work was done in 1940 & 1941. The time frame would explain our not having any drawings for this helmet. At some point in the company's history the file containing all drawings done in 1941 went missing. We have drawings from 1940 and 1942. The finding of the patent at least gives us some insight into the design and manufacture of this helmet. It also will help identify some of the old wood patterns we have in boxes around here.

We don't have any blueprints or patterns from the Model 100 Helmet. It did appear in the 1946 catalog. the text read;

Browne Self-Contained Suit Model 100 Cat. No. 29132

This model is similar in design and operation to the Model 106, with the exception of the breathing apparatus.

In this suit the diver carries both the oxygen cylinder and canister on his back. In place of a mouthpiece, the diver holds his face into a mask which directs the circulation of air through the canister. Diving depths and time limits with this model are comparable to the Model 106.

Weight 135lbs. Standard size only.

Model 106 Helmet

The Model 106 is similar to the Model 100. The main difference is that the Model 106 used a mouthpiece instead of a oral/nasal mask for breathing.

We don't have any blueprints or patterns from the Model 106 Helmet. It did appear in the 1946 catalog. the text read;

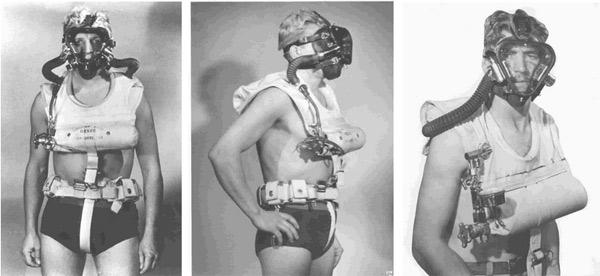

Browne Self-Contained Suit Model 106 Cat. No. 29133

This portable suit was especially designed for light salvage and inspection work. It is particularly adaptable to commercial divers who wish to make inspections or short salvage jobs where it would not pay to haul heavy equipment to the location. The Browne two piece dress which joins at the waist is used to facilitate handling and dressing. No breastplate is used. The diver carries oxygen cylinders compressed to 2000 pounds on his back, while the combined canister and chest weight hang on the diver's chest. The control valve hangs conveniently at the diver's waist.

The mouthpiece which the diver grasps lightly in his mouth is for breathing. many divers prefer this breathing system. this suit has been used for three hours in 20 feet of water and to 60 feet for 1 hour when pure oxygen is used. Short dives may be made to over 120 feet if the diver uses compressed air.

The helmet is constructed of spun Copper heavily coated with Tin and all fittings, including those on the suit, are of polished cast Brass. Windows are of clear, durable plastic. The case holding the oxygen cylinders is metal. Photos show the diver with combination telephone and lifeline cable. Dresses are supplied in light or heavy weight and in sizes A, B, and C.

Weight 135lbs. complete

Buie Mixed Gas Helmets

During WW II pressure was kept on manufacturers to develop new and better equipment. Not just rifles, or planes, or tanks but in every area. DESCO was tasked with making continual advances in diving equipment to meet the challenges that arose daily during the war. The Navy had been experimenting for years with Helium diving using converted Mark V helmets. This was a practical approach as they were well familiar with the helmet and they were readily available. When the war broke out the status quo changed and this allowed for experimentation on a level not dreamed of before. U.S. Navy diver E.D. Buie came to DESCO to work on a low volume mixed gas helmet for the Navy to use clearing mines.

The first low volume mixed gas helmets had a curved window. The canister was much smaller than the Mark V Helium canister and in fact the whole helmet weighed less than half of the Mark V Helium (104lbs to 43lbs). The smaller and lighter rig was needed for mine clearance work. Not many units were made. DESCO was lucky enough to acquire a early helmet for our collection. It was missing the canister but we fortunately had the patterns for the end caps and were able to make one. It is incomplete but is good enough for display purposes. We are not aware of the location of any of the later Buie helmets.

The basic design in the form of the shell, air inlet, and canister remained constant. The main difference in the later Buie helmets is the front window. A curved helmet can cause distortion in the field of vision underwater. This would not be good while working on a mine. Later Buie helmets have a faceted window presenting flat surfaces to the water. The secondary exhaust valve was changed from the original design.

As with much of the WW II technology from many industries DESCO offered equipment developed for the Navy to the commercial market after the war. In the 1945/46 catalog the Buie helmet was offered along with a complete outfit.

As the war wound down DESCO needed to develop products to compete with a potential glut of surplus diving equipment. The Browne Utility Helmet was a stripped down version of the Buie Helmet. It eliminated the entire gas system, and the complex front window assembly from the Buie helmet. It was offered beginning in the 1945 catalog as a alternative to the standard gear. The Browne Utility helmet would be the first low volume helmet to hit the market, some twenty years before the Savoie or DESCO

A interesting historical tidbit is our discovery that E. D. Buie took out a patent on the outfit in 1953. It is curious as DESCO did the prototyping, and production of the helmet for the Navy. Since a patent was issued there must not have been any objections from the other invested parties. Click to view a pdf of the Buie patent.

Variant Mixed Gas Helmet

We don't know much about this variant at all. There is only one example that we are aware of in a private collection. We have a few patterns but no drawings

The canister is permanently soldered to the helmet shell so it was intended to be used as a gas hat only. The Buie helmet canister could be removed and the elbows capped and it would work like a normal free flow helmet.

We believe that this helmet design may have been developed concurrently with the Buie, or as a follow on design. This canister configuration makes the helmet more streamlined and less complicated to build and maintain. There are less protrusions creating potential snagging hazards. The concept may have been proposed by Buie himself or the DESCO designers as the helmet was being designed for mine clearance duties. Reducing the risk of snagging on a mine cable would be a practical goal.

In the Fall 2009 issue (#61) of The Journal of Diving History is an article on this helmet. It states that consensus in the HDS believes this helmet is an early version of a Buie. Later in the article they quote for Mr. Buie's 1983 book Dear Mother, I did not dive into the Ocean Today that they were fortunate that DESCO would produce prototypes on demand. We have no way of knowing how many prototypes may have been made, or what they looked like.

I'm inclined to believe the bolt on canister was a standard detail on the Buie helmet from the beginning. The Navy would have been accustomed to this style from using the Mark V Helium helmet. The injector system would have most likely been nearly identical. Being able to swap parts, especially delicate injector hp jets would have been desirable. A best guess is that this helmet is one of the prototypes requested by E. D. Buie.

The CO2 absorbent is added through the cap in the center of the canister, where the Buie had a door on the side for installation of a cartridge.

Bob Kirby Recirculator Helmets (on DESCO lightweight helmets)

DESCO is fortunate to have two of the early Kirby/DESCO helmets in our collection.

|

|

| Kirby Recirculator Helmet on DESCO 1043 | Kirby Recirculator Helmet on DESCO 1084 |

In his book "Hard Hat Divers Wear Dresses" Bob Kirby says he made six of these helmets on DESCO Sponge helmets. He moved over to Yokohama helmets for subsequent units.

The polished helmet is DESCO s/n 1043. The plated one is DESCO s/n 1084. We think 1043 may be the first one of the six. Bob describes the evolution of the helmets in the book and the description of the first one fits 1043.

Excerpt from Hard Hat Divers Wear Dresses page 154 :

I was instructed to build five more hats for a total of six gas rigs - Associated's passport to success. Or so we thought at the time.

All hats were built on Desco sponge-helmet frames. The first hat had thin plastic view-port lenses and the last five had one-inch thick plastic screw in ports - a far safer design and one I would continue to use in future Kirby Commercial Helmets.

Once we had completed and tested the first hat, I determined the navy's method of pumping gas through the absorbent could be improved. I turned the entire system around so that, instead of pushing the gas, the venturi would pull the gas through. This proved to be far more efficient.

|

|

| The injector assembly on 1043 points towards the rear of the helmet. The injector assembly on 1084 points forward. | |

Recirculator Helmet 1043

1043 still has the Sponge type front, side and top windows. The front base was extended. The side and top windows have thinner acrylic than standard and are fitted with o-rings. It has a Morse air control valve. It is fitted with a Mark V telephone cup and a commercial style comm elbow.

Recirculator Helmet 1084

1084 "looks" more refined than 1043. The injector system is the later design.

After the first six helmets were built Kirby switched to Yokohama helmets as a base.

|

|

| DESCO based Kirby | Yokohama based Kirby |

DESCO Rebreathers

DESCO began producing equipment for the U.S. Navy in 1942 to support the war effort. The Office of Strategic Services (forerunner to the CIA) needed rebreathers for covert operations. DESCO was contracted to design and produce the needed units. After that contract was completed subsequent units were sold to the Navy. With the end of WW II DESCO applied the technology to commercial and sport diving. SCUBA was still a few years away from wide acceptance. To supplement the commercial equipment business DESCO also marketed a line of sporting goods. The A-lung was targeted to this market segment. It was small and simple to use. The B-lung was the unit that DESCO developed during the war and was aimed at the commercial diver. The C-lung was a DESCO lightweight suit fitted with a heavy duty rebreather. In the late 40's and early 50's a fatal flaw in rebreathers surfaced. The breathing of pure oxygen under pressure caused a buildup of oxygen in the body actually poisoning the user. Several accidents caused manufacturers to reconsider the use of rebreathers by amateurs. This and the emergence of SCUBA compressed air tank diving spelled the end of production of rebreathers for sport use at that time. Today new technology has allowed rebreathers to make a comeback by onboard computers monitor the system thus reducing the risks.

Here is a look at the DESCO rebreathers.

The DESCO A-Lung

Also known as the Adventurer, and the Sportster Lung. This unit was designed in the early 1950's. It was a simpler, more compact design than the B-Lung. The unit evolved during its short run. Early units had a canvas breather bag, while later units had a vinyl bag. The A-Lungs were only produced for a few years in the mid-50's.

To download a copy of the A Lung Instruction Sheet click here .To download a copy of the A Lung Instruction Sheet click here.

Notice: These instructions are provided for informational purposes only. Due to the age of this equipment, and the inherent danger in the use of the old rebreathers, DESCO strongly recommends that these units are never used for diving.

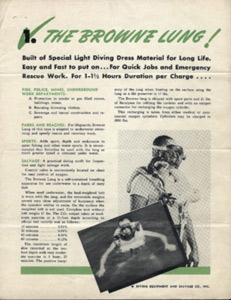

The DESCO B-Lung

Also known as the Buccaneer Lung. This is the unit first developed for the OSS and U.S. Navy during WWII. The first units used a oval mask with a nose bump out. Later units were fitted with a modified Jack Browne mask. B-Lungs were produced until the early 1960's. On the 1960 DESCO pricelist the B-Lung cost $205.00.

Above photos show a early B-Lung with the oval mask and a nose bump out.

Below photos show a later unit equipped with the Jack Browne triangular mask.

To download a copy of the Browne Lung Instruction Sheet click here.

To download a copy of the Buccaneer Lung Instruction Sheet click here.

Notice: These instructions are provided for informational purposes only. Due to the age of this equipment, and the inherent danger in the use of the old rebreathers, DESCO strongly recommends that these units are never used for diving.

The DESCO C-Lung

The C-Lung is a DESCO Lightweight Suit mated to a rebreather unit on the diver's back. This configuration allowed the diver to remain completely dry.

|

|

Literature pertaining to the DESCO Rebreathers

|

|

|

Lindbergh - Hammar Associates

PURA 787 CO2 Removal System

In 1969 DESCO partnered with Lindbergh - Hammar Associates to produce and market a lightweight Helium helmet using the DESCO Air Hat and LHA PURA CO2 Scrubber system. Jon Lindbergh was the second child of Charles and Anne Morrow Lindbergh.

The PURA system was a electrically powered, turbine pressurized unit which circulated mixed gas through the helmet and back to a CO2 absorption canister. The larger LHA PURA system used for recompression chambers, underwater habitats, personnel transfer capsules, and medical hyperbaric chambers. The helmet unit was mounted to a backpack. It was based on the larger unit's technology.

Unlike the U.S. Navy's standard Helium helmet, based on the Mark V, which used a venturi system to move the gas mix, the LHA system used a electrically powered turbine to force the gas mix through the system. A venturi system requires new gas to be pumped into the system for recirculation and this results in gas loss through the exhaust valve.

0 Item(s)

0 Item(s)