Diving Helmet Details

The various features on different style diving helmets.

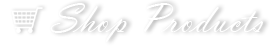

Diving Helmet Exhaust Valves

We're starting with exhaust valves as there is more variety in this component than any other.

Exhaust valves are an essential component of the helmet as what goes in must come out. Differences in exhaust valves are mainly in the location and the amount of control they provide. Also the point at which the gas escapes the valve may differ considerably.

The Sponge Helmet Exhaust Valve

This is the most basic exhaust valve design. The Sponge Helmet exhaust is a single spring, non-adjustable, head butt valve mounted on the right rear of the helmet top. One spring applies pressure to the valve stem to hold the predetermined overpressure in the suit. The valve does not have any ducting and vents through holes spaced around the perimeter. The suit can be "dumped" by opening the valve all the way using the back of the head against the button on the valve stem.

The Agar Helmet Exhaust Valve

The Agar Helmet exhaust is a single spring, adjustable, head butt valve mounted in the same location as the Sponge Helmet exhaust. The central body is cut from a Mark V exhaust banana casting. The "bonnet" is male threaded and the body is female threaded, which is reverse of a Mark V exhaust valve. The Star wheel is a Mark V casting without the internal threading for the spring retainer. It is held in the bonnet by a stop ring soldered on after assembly. A duct extends downward with vent holes drilled along the perimeter and on the face.

The Abalone Helmet Exhaust Valve

The Abalone Helmet Exhaust Valve

The original design of the Abalone Helmet called for an exhaust valve which was a combination of the USN Mark V valve banana and the Agar single spring valve. Later (and current) Abalone helmets use the standard Mark V double spring exhaust valve. The "banana" tube vents the helmet behind the right side window to prevent the escaping air obscuring the divers view.

The Browne Commercial Helmet Exhaust Valve

The Browne Commercial Helmet exhaust valve is actually a double exhaust valve. The primary exhaust is a standard USN Mark V valve assembly with a secondary, non-adjustable, rubber flapper exhaust valve in it's own housing. The two valves are joined by a duct. The helmet vents through holes in the perimeter of the secondary exhaust cover. The suit can be dumped by activating the valve with the back of the head.

The US Navy Mark V Exhaust Valve

The US Navy Mark V Helmet exhaust is a double spring, adjustable, chin activated valve. When the star wheel is fully closed the secondary spring provide the preset cracking pressure for the valve. This allows for pre determining how much overpressure will be in the suit at fully closed. The "banana" tube vents the helmet behind the right side window to prevent the escaping air obscuring the divers view.

The US Navy Helium Helmet Exhaust Valve(s)

The US Navy Helium Helmet Exhaust Valve has two versions. The early helmets had a exhaust duct which ended in a bulb just like the banana tube. This duct rose vertically from the main body over the top of the helmet and terminated near the elbows. It was found that salt water could leak back into the helmet. If this water were to mix with the CO2 absorbent it would form chlorine gas. In the early 1950's the design was changed to add an additional non-adjustable double exhaust valve on the top of the helmet. This in essence made the valve a "triple exhaust". The primary valve is a standard Mark V assembly.

The Browne Utility Helmet Exhaust Valve

The Browne Utility Helmet exhaust is a double spring, adjustable, double exhaust valve. The primary valve assembly is standard USN Mark V, and the non-adjustable secondary valve is a rubber faced Brass disk with a single spring. The valve vents out four large holes in the secondary valve cover.

0 Item(s)

0 Item(s)